We managed to pump out most of our contaminated bilge water. A combination of rain ingress, spilled oil and diesel from Rosie’s previous owner meant we had about 15 litres of yuk to pump into bottles to get rid of. We used Bilgex and gave the areas I could reach a good scrub, it is much better, perhaps less than a litre that needs to be sponged out now, that might even evaporate away in the warm weather over the next week.

At last, it was time to tackle our misbehaving gearbox.

Our engine is a 23hp Volvo Penta MD11C fitted in 1979. Still with original Volvo MSB gearbox. The engine has seen better days at least cosmetically, there are rusty bolts and green engine paint is starting to flake off places, this is not a surprise especially considering amount of moisture we removed from the engine bay. But, it started well yesterday and with a minimum of smoke compared to our cold weather first trip. But, the gearbox has been getting stuck in reverse, where I’d have to cut fuel off and stop the engine before being able to get out of reverse gear. Reverse also made a rather worrying noise.

You might be able to make out the grey sparkle blobs on the middle of the gearshift control and above on the water pipe. This was spurted out of the top of the gearbox at some recent point. Both this happening at all and the metal bits it contained made me think there are serious problems with our old gears here. So armed with a new O-ring, spanners and lots of oil absorbent pads we started by disconnecting the gearshift control to make for easier access to the bolts holding the top plate in.

Luckily, somehow the only ring spanner we actually owned fitted these perfectly. After cleaning away loose paint, oily-blobby rust-water buildups nearby we were able to get the top of the gearbox out to see if true horrors waited for us inside.

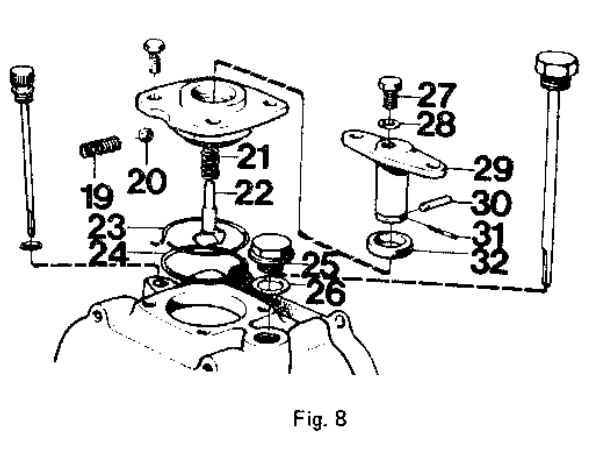

If you do this yourself, beware that there will be things that will want to fall out the top part of the gearbox. There is a large metal “V” shaped shift control thing (Part 839646 – called a “Slide cone” or “dog” or “sliding shoe”) and it’s spring. These will most definately try to make a break for freedom or worse retreat inside the gearbox (part 21 and 22 below)

EDIT: Now that I look at the diagram above, I notice that 19 and 20 were totally missing from our gearbox! I can’t see what purpose they hold… – EDIT2 turns out that later gearboxes don’t have them. Phew.

The thing here marked as #1 is the actual business end that puts the drive in and out of gear. In this upside-down image from the overhaul PDF you can’t see the spring that goes around the top of it.

Once off, it was a little yuck, but no large lumps of metal debris thankfully.

Here is the “V – slide cone” and top left it’s buddy “the spring”. Quite worn but still able to do it’s job for a while more hopefully. Might see if I can get another.

The spring goes into the middle hole and the round end of the V goes in next. This all “looked” OK to me, but we gave it a bit of a clean up inside and out.

I had an oil scavenger pump (found in the aft locker) so set to work trying to slurp out the old oil from the gearbox. I got about 300ml out before the pump gave up. Also, because the gearbox had not been running, none of the worrying silver bits were in any of the oil I pumped out. Deciding I needed a new pump I planned to pack up, go home, get a new pump and resume the job next weekend. So I thought rather than leave the gearbox open to the elements I’d put it all back together, maybe next time I’d use the pump via the dipstick hole instead.

It was on this first re-assembly attempt that “spring” and “v” made a break for it and ended up inside the gearbox..

Bother..

Cursing myself, thinking about how difficult it would be to get the whole gearbox out by myself while on the mooring or how much the nearest boatyard might charge to do the work for me I realised my last hope would be to see if I could grab the bits out somehow. I needed some kind of grabby claw that I could fish about with to get them out.

We locked up and drove to Latham’s. The Huge shop that has been a fixture of the Broads for decades. It’s grown considerably since my first trip there aged about 7 to buy fishing floats. It is stocked to the brim with far more than I was expecting and is not simply there to serve caravan or broads holiday makers.

The unexpected bonanza of bits we picked up were:

- Bendy MAGNETIC telescopic grabber

- Straight magnetic telescopic rod

- New oil scavenger pump

- Replacement dry powder fire-extinguisher and mounting bracket

- Tuna mayonnaise baguette

- Haribo

With the unexpected purchase of a better pump and the bendy magnetic grabber we were able fish the two parts out and drain most of the oil away.

Re-filled with some 20W mineral oil and put everything back together (carefully) and finally it was time to start the engine (and hope no other bits had fallen in that we’d not noticed).

So, after a bit of a clean up and a rushed oil change the gearbox now will actually come out of reverse with a bit of firm pressure. Still not right but a step in the right direction.

Next trip I will do a more thorough oil-rinse out, I’ll run the gearbox for a couple of minutes and then siphon out the mixed oil before it settles and replace, perhaps do that twice and see how things pan out

One thought on “Gearbox Grind”